Nanopatterning on the cylindrical surface using an E-beam pre-mapping algorithm

- Journal

- Journal of Micromechanics and Microengineering

- Vol. (No.), pp.

- 29 (1), 015004 (Jan 2019)

- Year

- 2020-2014

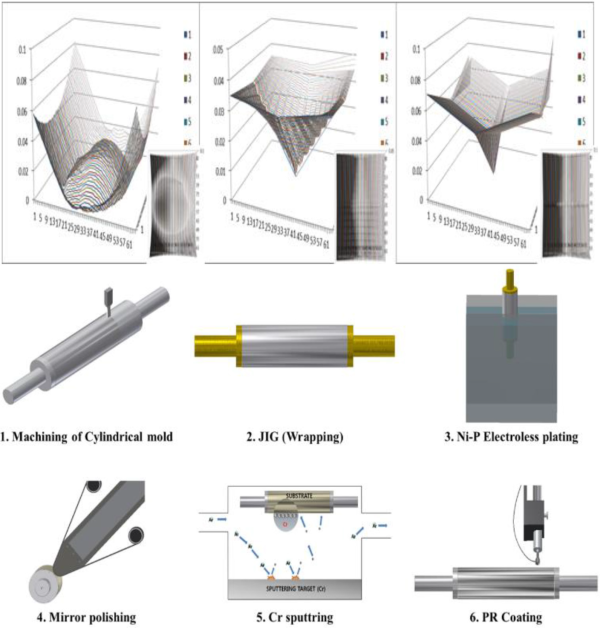

Lithography technology has advanced from flat plates to cylindrical surfaces, aiming to address the emerging needs in flexible and mass-customized applications. Nanoscale ultra-precise patterns have benefited from advanced lithography techniques also involving precision stage technology and material development. While conventional lithography mostly relies on flat wafer-base processing, fabricating nanopatterns on cylindrical surfaces can further expand the applicability and productivity of nanoscale lithography, for example, by integrating with the continuous and scalable plate-to-roll or roll-to-roll nanopatterning techniques. In this regard, we develop a novel nanopatterning methodology that can directly create a nanoscale pattern on the surface of a cylindrical mould by utilizing the E-beam pre-mapping algorithm for uniform E-beam exposure. Here, E-beam pre-mapping was employed to ensure uniform exposure over the cylindrical surface from the planar E-beam source, where the trajectory of the E-beam is modulated along the curved surface of the cylinder based on the pre-calibration of the surface profile. We design and build up a cylindrical exposure system with an E-beam gun that can move at a high degree of freedom. We also perform in-depth analytic modelling and profiling of the target curved surface, which is an essential step for applying E-beam pre-mapping for uniform exposure. By conducting the developed process, we finally achieve a very fine 60 nm scale half-pitch pattern on the cylindrical surface, which may be further extended to enable direct nanopatterning on curved surfaces for many unique applications.